Do you require load testing services for your commercial, industrial, residential, or municipal projects? Hale Built has become a trusted name in the mid-Atlantic for accurate and reliable tension and compressive load testing solutions. With years of experience serving various industries and properties across New Jersey and the Mid-Atlantic region, we have built a reputation for excellence and professional customer service.

When it comes to load testing, we understand that precision is key. That’s why our expert team of contractors understands the importance of comprehensive and tension load testing to ensure structural integrity. We’re proud to offer top-notch testing services that meet industry standards and exceed expectations. So why leave your project's structural stability to chance? Trust our reliable load-testing solutions to give you peace of mind.

Call or contact us today to discuss how we can assist you with your commercial load testing needs.

Tension and compression load testing are essential to evaluate materials' structural performance and integrity under different forces. In tension load testing, materials are subjected to pulling or stretching forces to assess their strength and ability to resist elongation. On the other hand, compression load testing involves applying compressive forces to assess the material's ability to withstand squeezing or crushing. These testing methods are crucial in construction, manufacturing, and engineering industries, where the reliability and safety of structures and components are paramount.

Tension and compression load testing serve several purposes, including determining the load-bearing capacities of materials, identifying potential weaknesses, and ensuring compliance with industry standards and specifications. By subjecting materials to controlled loads, engineers can assess their behavior and performance, aiding in designing and selecting suitable materials for various applications.

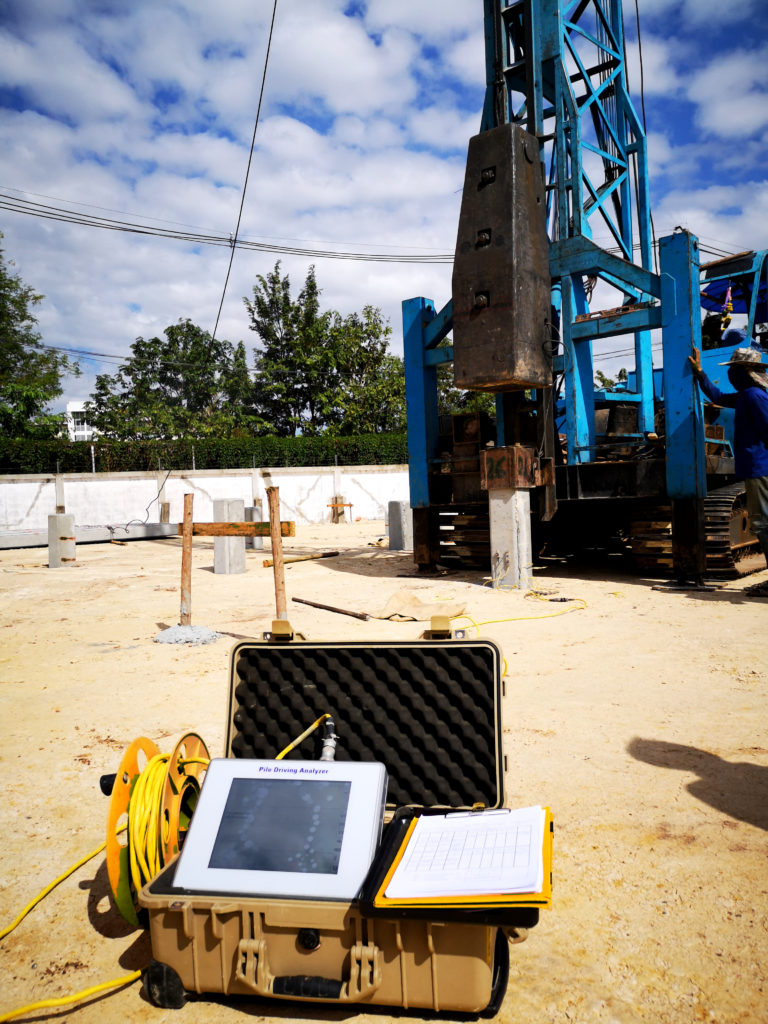

We provide comprehensive tension and compression load testing services at Hale Built Group in New Jersey and the surrounding areas. Our experienced team, specialized in industry code 1810.4.1, utilizes state-of-the-art equipment and follows standardized procedures to accurately measure and analyze the performance of materials under different load conditions.

We also work closely with our clients to understand their testing needs and provide reliable results that inform decision-making processes. Whether you require tension or compression load testing for structural components, building materials, or specialized products, our expertise and commitment to quality ensure that you receive accurate data and valuable insights.

Commercial compressive load testing and tensile load testing are essential job requirements for engineers to evaluate the strength and durability of structures under different conditions. Using component specimens, these two types of load testing help assess the structural integrity and specification of deep foundation repair. The distinction between compressive and tensile load testing lies in their impact on structural integrity, with compressive load testing measuring resistance to psi and tensile load testing measuring resistance to stretching forces. Both types of load testing are crucial for ensuring the safety and longevity of structures.

Commercial Compressive load testing in New Jersey & the mid-Atlantic involves subjecting specimens or materials to inward forces to assess their ability to withstand compression. This testing is critical for determining the average load-bearing capacity of a structure. In contrast, tensile load testing evaluates a structure's resistance to stretching or pulling forces. Engineers can determine if a structure meets the specified criteria without breaking by applying tensional forces.

Both compressive and tensile forces can significantly impact structural integrity but in different ways. Compressive forces tend to cause structures to buckle or collapse under excessive pressure. Therefore, understanding a structure's ability to handle compression is vital for ensuring stability when subjected to heavy loads such as buildings or bridges. This understanding can be obtained by conducting strength test results on specimens.

Tensile forces, on the other hand, test a structure's resistance against stretching or elongation. Structures that fail under tensile stress are prone to cracking or breaking apart when subjected to pulling forces. Evaluating tensile strength helps engineers identify potential weak points in structures and design reinforcement strategies accordingly. Specimens are used to evaluate tensile strength.

Commercial deep foundation repair is a critical process that ensures the stability and longevity of structures across various industries. One crucial aspect of this repair work is compressive load and tension testing. These tests are vital in identifying potential weaknesses, ensuring structural stability, and preventing future damage. Let's explore why compressive load and tension testing are essential for deep foundation repair.

Compressive load testing involves subjecting a structure or component to significant pressure to evaluate its strength and capacity to bear weight. On the other hand, tension testing assesses the ability of materials to withstand stretching or pulling forces. Both these tests are fundamental in determining the structural integrity of deep foundations.

Engineers can determine if a foundation can withstand heavy loads without experiencing excessive settlement or failure by conducting compressive load tests. This assessment is crucial for industries such as construction, oil and gas, transportation, and manufacturing that rely on robust infrastructure capable of supporting heavy equipment or machinery.

Tension testing complements compressive load testing by evaluating how well materials resist stretching forces. This test helps identify any weaknesses in the foundation that may compromise its overall stability when subjected to tensile stresses. By addressing these weaknesses during repairs, engineers ensure that the repaired foundations can effectively withstand compression and tension forces.

The importance of compressive load and tension testing extends beyond individual projects; it impacts entire industries reliant on strong foundations. In construction, for instance, commercial buildings with weak foundations pose significant risks to occupants' safety and lead to costly repairs. Compressive load and tension tests help identify potential issues early on so that necessary measures can be taken to reinforce foundations before construction begins.

For industries involving heavy machinery or equipment, such as oil and gas or manufacturing, the stability of foundations becomes even more critical. Compressive load testing ensures that these structures can handle the weight and vibrations generated by heavy machinery without compromising safety or causing damage to surrounding infrastructure. Tension testing, on the other hand, helps prevent catastrophic failures due to tension forces exerted during operation.

Accurate compressive load and tension testing are essential for immediate repairs and preventing future damage. Engineers can implement targeted repairs that address underlying issues by identifying weak points in deep foundations. This proactive approach reduces the likelihood of future structural failures and minimizes costly repairs or downtime.

Furthermore, accurate load testing allows engineers to accurately determine each design specification for new or complex construction projects. Understanding how materials perform under different loads and tensions can create robust foundations that meet industry standards and regulations. This attention to detail ensures long-term structural stability while avoiding unnecessary expenses caused by inadequate designs.

Ensuring the final product meets the job specifications and acceptance criteria is crucial in the construction industry. Compressive strength testing plays a vital role in this process, providing valuable insights into the structural integrity and performance of the materials used. Our experienced team conducts comprehensive compressive strength tests on various materials, including concrete and steel, in accordance with industry specifications and municipal regulations across New Jersey & the Mid-Atlantic.

Manufacturers can confidently assess whether their products meet the specified requirements by analyzing the average strength test results in terms of psi (pounds per square inch). Our tests are carried out meticulously, following precise procedures to deliver accurate data in psi that aids structural engineers in evaluating the suitability of materials for a project. With our compressive strength testing services, you can have peace of mind knowing that your products comply with job specifications and are ready for acceptance.

Neglecting compressive and tensile strength tests can have severe consequences for the structural integrity of a commercial building. Inadequate testing poses potential risks and leads to costly repairs and, in worst-case scenarios, catastrophic failures.

Uncovering the potential risks associated with neglecting these tests is crucial. A structure subjected to a commercial compressive load without proper testing may not withstand the applied force. This puts the entire structure at risk of failure. Without knowing the limits of a building's compressive strength, there is no way to ensure its safety under normal operating conditions.

Similarly, neglecting tensile strength tests can have detrimental effects on structural integrity. Tensile forces exert pulling or stretching pressure on materials, which can cause them to deform or eventually break apart. By ignoring these tests, engineers leave structures vulnerable to such forces without knowing their resistance capabilities.

The negative impact on structural integrity due to inadequate testing cannot be overstated. Structures that have not undergone proper compressive and tensile strength tests are more susceptible to various damage over time. Cracks may develop in load-bearing components, compromising the overall stability and safety of the structure. Moreover, weak points within the construction may go unnoticed until they reach critical levels.

Neglected compressive and tensile strength tests often lead to costly repairs down the line. When structural weaknesses are discovered after construction is complete, rectifying them becomes significantly more expensive than if they had been detected earlier through thorough testing. Repairs may involve reinforcing weak areas or even replacing entire sections of a building or infrastructure.

In some cases, neglecting these essential tests can result in catastrophic failures with devastating consequences. History has witnessed numerous instances where buildings collapsed due to unforeseen weaknesses caused by inadequate testing practices. These failures cost lives and have long-lasting effects on public trust in engineering and construction practices.

To emphasize the importance of commercial compressive load testing, it is crucial to highlight real-life examples where neglecting these tests led to disastrous outcomes. The collapse of the Morandi Bridge in Genoa, Italy, is a stark reminder of what can happen when structural integrity is compromised. In this case, insufficient attention to maintenance and testing resulted in the tragic loss of 43 lives and significant damage to surrounding infrastructure.

When evaluating the average strength test results of structural components, manufacturers and structural engineers in New Jersey & the Mid-Atlantic rely on rigorous procedures to ensure the quality of their products. Compressive strength testing is essential in this process, as it determines whether a product meets the acceptance criteria specified by the structural engineer and job specifications.

Our team of experts conducts thorough compressive strength tests in accordance with industry standards and local regulations, ensuring that every product is tested and evaluated accurately. By adhering to these procedures, manufacturers can have confidence in the quality of their products and meet the requirements set forth by structural engineers. Whether it's testing concrete, steel, or other materials, we provide comprehensive compressive strength testing services tailored to the unique needs of our clients in New Jersey & the Mid-Atlantic.

Call our inspection specialists today for a free to low-cost project quote!

Structures are subjected to various forces and loads throughout their lifespan. Over time, these forces can take a toll on the structural integrity of buildings, bridges, and other constructions. To ensure the safety and longevity of your structure, it is crucial to recognize the signs that indicate a need for compressive and tensile load testing.

If your property experiences any structural issues or other concerning signs of deterioration, we urge you to call or contact us as soon as possible for load testing services. We invite proprietors to get started on the path toward restoring a structurally sound business with a comprehensive estimate of our load testing services.

Understanding warning signals associated with potential issues in your structure's strength is crucial to prevent catastrophic failures. By recognizing these signals early on, you can take proactive measures and ensure the safety of occupants.

Deep foundation damage can occur due to various factors, necessitating load testing, and subsequent repair. Understanding the causes behind such damage is crucial in identifying and addressing underlying issues that may compromise the structural integrity of a building or infrastructure. Let's explore some of the key reasons deep foundation damage occurs and why load testing is critical in mitigating these risks.

One of the primary causes of deep foundation damage lies in the soil conditions surrounding a structure. Different soil types have varying load-bearing capacities, with some being more stable than others. For instance, expansive clay soils are notorious for their tendency to shrink and expand with changes in moisture content, exerting significant pressure on foundations. Similarly, loose or sandy soils may lack the stability to support heavy loads adequately.

External forces also play a significant role in causing deep foundation damage. Natural disasters such as earthquakes, floods, or hurricanes can subject structures to excessive stress and strain beyond their design limits. Even without catastrophic events, regular exposure to environmental factors like temperature fluctuations and ground movement can gradually weaken foundations.

During the construction process, several deficiencies can compromise the strength and stability of deep foundations. Poor workmanship, inadequate materials, or design errors contribute to potential weaknesses that may go unnoticed until it's too late. If left unaddressed, these flaws can lead to settlement issues, uneven weight distribution, and even structural failure.

As buildings age, so do their foundations. Over time, wear and tear take their toll on structural elements below ground level. Corrosion of reinforcement bars within concrete piles or degradation of wooden pilings are common examples of how aging infrastructure can lead to deep foundation damage. Regular load testing becomes essential in detecting and rectifying any deterioration before it escalates into a more significant problem.

Load testing is crucial in identifying underlying foundation issues that may not be immediately apparent. By subjecting the deep foundation to simulated loads, engineers can assess its performance and determine if any weaknesses or deficiencies exist. This process helps pinpoint areas of concern and provides valuable insights for subsequent repairs or reinforcement measures.

Deep foundation repair services offer a wide range of solutions to enhance the structural strength of buildings. Whether it's reinforcing compressive or tensile strength, these techniques provide effective and tailored solutions for your unique foundation needs. Let's dive into some specific methods experts use in commercial compressive load testing to ensure the longevity and stability of your concrete structures.

Several techniques have proven to be highly effective. These methods involve strengthening the concrete and ensuring its ability to withstand significant loads.

Tensile strength is equally crucial. Professionals employ various techniques tailored to each unique situation to reinforce this aspect.

At Hale Built Group, we pride ourselves on our comprehensive process and protocols for commercial compressive load testing. We understand the importance of accurate load tests in deep foundation repair projects, so we have developed a meticulous approach that ensures reliable results every time.

It is crucial to have a thorough understanding of the structural integrity of the foundations. Our compressive and tensile load testing procedures are designed to assess the strength and stability of these foundations under different types of loads.

Our process begins with a detailed analysis of the project requirements. We collaborate closely with our clients to gather all relevant information about their needs. This includes understanding the type of structure, soil conditions, and any issues that need addressing.

We conduct compressive and tensile load tests once we have gathered all the necessary information. These tests involve applying controlled pressure or tension to the foundations to measure their response. By doing so, we can accurately determine their load-bearing capacity and identify potential weaknesses or areas needing reinforcement.

To ensure accurate results, our team follows a structured approach when conducting compressive and tensile load tests for deep foundation repair:

Our commitment to accuracy and attention to detail sets us apart. We understand deep foundation repair projects require precise measurements and reliable assessments, so we adhere to strict protocols throughout our testing process.

Following these protocols can give our clients dependable results that inform their decision-making process. Whether determining the need for reinforcement or evaluating the structural integrity of existing foundations, our comprehensive approach ensures you have all the information you need to proceed confidently with your project.

Deep foundation repair projects require a thorough understanding of the foundations' structural stability and long-term durability. One crucial aspect of this assessment is compression and tension testing. These tests are crucial in evaluating the strength and integrity of deep foundations, helping to prevent future issues and ensuring the safety of structures.

Compression and tension testing provides valuable insights into how well a deep foundation can withstand external forces. Engineers can determine its load-bearing capacity by subjecting the foundation to controlled loads, identifying potential weaknesses, and assessing if it meets design specifications. This information is crucial for making informed decisions about repairs or modifications needed to ensure the stability of the structure.

During compression testing, a compressive load is applied vertically to simulate a foundation's weight over time. This test helps evaluate how well a foundation can resist downward pressure without excessive settlement or deformation. It also allows engineers to detect any instability or failure that could compromise the overall structure's safety.

On the other hand, tension testing involves applying forces that pull apart or stretch the deep foundation horizontally. This test helps assess its ability to withstand lateral loads such as wind or soil movement. Engineers can determine if additional reinforcement or corrective measures are necessary to maintain structural integrity by measuring parameters like elongation and strain under tension.

Commercial compression and tension testing provide valuable data on current conditions and help anticipate potential problems in deep foundations. By identifying weak points during these tests, engineers can proactively address them before they lead to more significant issues.

For instance, if compression testing reveals excessive settlement or deflection under load, it may indicate inadequate bearing capacity or soil consolidation problems. With this knowledge, engineers can implement appropriate remedial measures like underpinning or soil stabilization to prevent further settlement and potential structural damage.

Similarly, tension testing can uncover vulnerabilities in the deep foundation's ability to resist lateral forces. Engineers can reinforce the foundation with additional support elements, such as tiebacks or ground anchors, if the test reveals excessive elongation or failure under tension. This proactive approach helps mitigate the risk of future issues caused by external loads, ensuring the long-term stability of the structure.

Load testing ensures the long-term durability and safety of deep foundations. Engineers gain valuable insights into their performance under real-world conditions by subjecting them to realistic loads during compression and tension tests.

These tests help verify that a deep foundation meets design requirements and performs as intended. They validate the structural calculations made during the design phase and ensure that all safety factors are adequately accounted for. Load testing also provides an opportunity to fine-tune designs, allowing engineers to optimize foundation systems for maximum efficiency while maintaining safety standards.

Commercial compressive load and tensile load testing are vital in modern-day construction. Engineers can determine their ability to withstand compressive and tensile forces by subjecting different types of supports to rigorous strength tests.

Various supports are evaluated during commercial compressive load testing to determine their strength and resilience. These supports include:

To obtain accurate strength test results during commercial compressive load testing, engineers focus on evaluating specific components within these supports:

By thoroughly assessing these components, engineers can gather crucial data that aids in designing safe and reliable structures. Understanding the behavior of different support types under varying loads is essential for maintaining overall structural integrity.

Understanding suitable compressive and tensile strengths is crucial. These strengths vary depending on industry standards, materials used, and specific project requirements. Achieving the appropriate strength levels is essential for guaranteeing optimal performance and durability. The following sections talk in more detail about each of these strengths, the importance of balancing them, and how to measure them for your project.

Compressive strength refers to a material's ability to withstand a compressive load without breaking or deforming. It is typically measured in megapascals (MPa) and plays a critical role in determining the structural integrity of various components such as concrete pillars, beams, or walls.

To ensure optimal performance, it is important to consider the specific requirements outlined in industry standards or project specifications. Different materials have different compressive strength requirements due to their unique properties. For example:

Meeting these specified requirements ensures that the structure can bear heavy loads without compromising its stability. Failure to achieve adequate compressive strength may lead to structural failures or safety hazards.

While compressive strength focuses on withstanding compression forces, tensile strength measures a material's ability to resist tension or pulling forces without breaking apart. It is equally important as compressive strength when considering structural stability.

Similar to compressive strength, tensile strength requirements vary based on industry standards and material characteristics. Some common examples include:

Understanding the appropriate tensile strength for a given material ensures that it can withstand external forces without experiencing structural failure. Neglecting to meet these requirements may result in cracks, fractures, or complete collapse under tension loads.

Achieving suitable compressive and tensile strengths is vital for maintaining long-lasting structural support and stability. Here's why:

By carefully considering industry standards, project specifications, and material characteristics when conducting commercial compressive load testing, construction professionals can guarantee optimal performance and durability of their structures.

Weak structures can pose significant risks to businesses, jeopardizing not only the safety of employees and customers but also the overall success and reputation of the company. When a building or infrastructure is not structurally sound, it becomes vulnerable to various hazards that can result in costly damages, injuries, or even fatalities.

One of the primary dangers associated with weak structures is the potential for collapse under a commercial compressive load. This can occur due to factors such as poor construction practices, inadequate materials, or aging infrastructure. The consequences of a collapse can be devastating, leading to severe property damage, business interruption, legal liabilities, and a tarnished brand image.

Another risk that weak structures present is reduced operational efficiency. If a building's structural integrity is compromised, it may limit the functionality and usability of different areas within the facility. This could result in disruptions to daily operations and hinder productivity levels. Moreover, it may require costly repairs or renovations to rectify these issues, further impacting the financial stability of the business.

Understanding the average cost in your region is crucial. By shedding light on pricing factors and industry-standard costs, we aim to help clients make informed decisions about load testing services. The following sections

Several factors come into play when determining the cost of compression tests. Understanding these factors can help you gauge why prices may vary and what to expect when seeking these services. Here are some key considerations:

While exact figures may vary depending on specific circumstances, understanding industry standard costs for compression tests provides a helpful baseline for comparison purposes. Most provided figures are general estimates and individual providers may have their own pricing structures. Therefore, it is advisable to contact several reputable companies in your area for accurate quotes tailored to your specific needs.

By offering transparency and insights into the average cost of compression tests in New Jersey and the Mid-Atlantic region, we aim to empower clients with the knowledge needed to make informed decisions about load testing services. Remember, always consider the factors affecting pricing and compare quotes from multiple providers before finalizing your choice.

Neglecting load tests can have severe financial consequences for businesses. It is crucial to understand the potential risks and costs associated with failing to conduct proper commercial compressive load testing. By highlighting these repercussions, we can emphasize the importance of investing in load testing as a proactive measure.

Early detection through load testing plays a significant role in saving substantial repair costs down the line. When loads are not adequately tested, structural weaknesses may go unnoticed until they manifest into major issues. This delay in identifying problems can result in costly repairs or even complete structural failures that require extensive reconstruction. Investing in regular load tests allows businesses to detect any vulnerabilities early on, enabling them to address them promptly and avoid more significant expenses later.

One of the key benefits of load testing is its ability to identify potential weaknesses before they become critical problems. By subjecting structures to varying loads, engineers can assess their resilience and determine if any modifications or reinforcements are necessary. Without this proactive approach, businesses run the risk of unexpected failures that could lead to catastrophic consequences both financially and from a safety standpoint.

Neglecting load tests also puts businesses at risk of non-compliance with regulatory standards. Many industries have specific regulations regarding the safety and stability of structures under various loads. Non-compliance can result in hefty fines or legal liabilities that further strain an organization's finances.

To illustrate the financial impact of neglecting load tests, consider these examples:

Load testing plays a crucial role in assessing the structural integrity and safety of deep foundations. However, there are distinct considerations for new deep foundations compared to older ones. Age impacts load testing requirements and approaches, leading to specific challenges and strategies for each scenario.

When dealing with new deep foundations, load testing is primarily focused on ensuring that the foundation can withstand the anticipated loads and meet design specifications. Here are some key points to consider:

Older deep foundations present unique challenges due to their age-related deterioration and potential changes in soil conditions over time. Here's what you need to know:

Ground-bearing capacity testing services are essential for construction projects in New Jersey and the Mid-Atlantic region. These tests assess the strength of soil to determine its suitability for supporting foundations. Accurate ground-bearing capacity testing is crucial to ensure safe and stable structures.

Understanding the ground-bearing capacity is vital before beginning any construction project. Without proper assessment, buildings may experience structural failures or uneven settlement, leading to costly repairs or even endangering lives. Therefore, it's imperative to rely on expert ground-bearing capacity testing services in NJ and the Mid-Atlantic.

During ground-bearing capacity testing, engineers perform a series of tests to evaluate soil properties such as density, moisture content, and compaction. They use specialized equipment like plate load testers or cone penetration tests to measure how much load the soil can bear without excessive settlement or failure.

The results of these tests help engineers determine the appropriate foundation design for a given site. Different types of soils have varying load-bearing capacities, so understanding this information is crucial for selecting suitable foundation systems such as shallow footings, deep foundations, or piles.

Here are some key points highlighting why accurate ground-bearing capacity testing is crucial for safe construction projects:

Hale Built Group stands as a trusted provider of certified construction services, holding the prestigious designations of Home Improvement Contractor (HIC), Small Business Enterprise (SBE), and Veteran Owned Small Business (VOSB). Our commitment to quality and compliance is evident in our compressive load and tension testing services, which adhere to industry standards and employ cutting-edge equipment.

By combining our certified expertise and advanced techniques, we offer clients in New Jersey a reliable resource for ensuring structural stability and regulatory conformity. Whether you're involved in government-owned projects, small-scale construction, or residential remodeling, Hale Built Group's certified solutions, supported by our SBE, VOSB, and HIC designations, provide the assurance you need for successful and compliant construction endeavors.

The frequency of load testing depends on various factors such as the age of your structures, environmental conditions, and industry regulations. It is recommended to consult with our experts who can assess your specific needs and provide guidance on an appropriate testing schedule.

Yes, absolutely! Load testing identifies potential weaknesses in deep foundations before they escalate into major problems. By addressing these issues early on, you can prevent costly repairs or even structural failures down the line.

The duration of a compressive load test varies depending on factors such as the size and complexity of the structure being tested. Our team will provide you with an estimated timeline based on your specific project requirements.

Yes, there are industry standards and regulations that govern load testing in various sectors. Our team is well-versed in these standards and will ensure that all necessary protocols and requirements are met during the testing process.

Gain peace of mind and ensure structural stability with Hale Built Group. Our reliable and comprehensive compressive load and tension testing services in New Jersey & the mid-Atlantic and the surrounding areas offer the expertise you need. With advanced equipment, adherence to industry standards, and a commitment to exceptional service, we provide accurate results to help you make informed decisions.

So why risk compromising the integrity of your projects?

Partner with Hale Built Group’s professionals and never have to worry about structural failure again. Start with a low-cost to free quote for our compressive load and tension testing services and take the next step towards reliable construction!